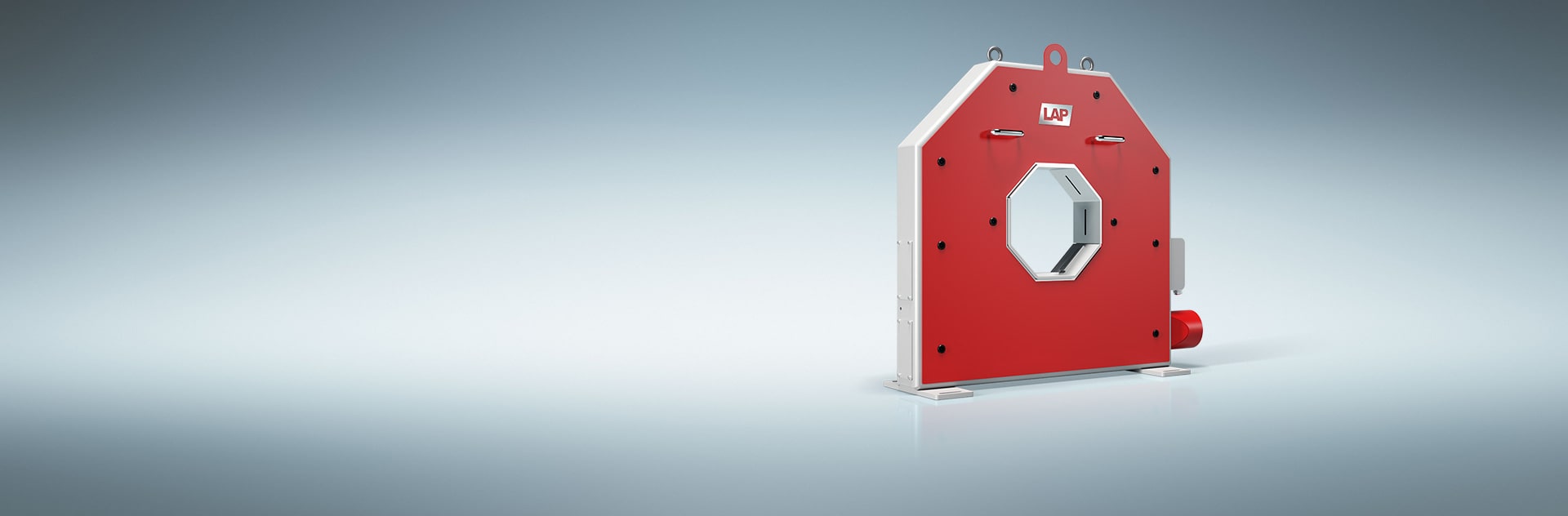

Laser measurement system for standardized quality control on round profiles and rebar

Increasing product quality is a major challenge in rolling mills. By means of a laser-based measurement system, the goal of a 100% geometry inspection can be achieved. The CONTOUR CHECK BAR & TUBE scans the steel profile inline and can determine diameter and ovality within seconds. The precise contour measurement also eliminates the need for many sample cuts, thus significantly reducing the cost of quality assurance.

In addition, the CONTOUR CHECK BAR & TUBE has the measuring ranges of 90 mm, 120 mm, and 150 mm, and can be used at material temperatures up to 200 °C. The software application developed by LAP analyzes quality-relevant errors and visualizes the measurement data in real time. Users can also intervene optimally in the ongoing rolling process in accordance with Industry 4.0.

SMART CORE ADVANCED Software

The software visualizes the core dimensions. In addition, the system warns of imminent tolerance violations, which can also be an indicator of a defect on the rollers.

Technical data

| CONTOUR CHECK BAR & TUBE 90 | CONTOUR CHECK BAR & TUBE 120 | CONTOUR CHECK BAR & TUBE 150 | |

| Measuring range | 90 mm | 120 mm | 150 mm |

| Accuracy (trueness) | ±20 μm | ±25 μm | ±30 μm |

| Repeatability (precision) | 0,0045 mm | 0,005 mm | 0,008 mm |

| Number of axes | 2 or 4 | 2 or 4 | 2 or 4 |

| Frame width | 1,100 mm | 1,580 mm | 1,580 mm |

| Frame height | 1,115 mm | 1,595 mm | 1,595 mm |

| Frame depth | 155 mm | 155 mm | 155 mm |

| Passline height | 565 mm | 805 mm | 805 mm |

| Frame weight | 200 kg | 370 kg | 390 kg |

| Positioning system | Yes | Yes | Yes |

| Blower | Yes | Yes | Yes |

| Air cooling unit | Optional | Optional | Optional |

| Pyrometer (optional) | No | No | No |