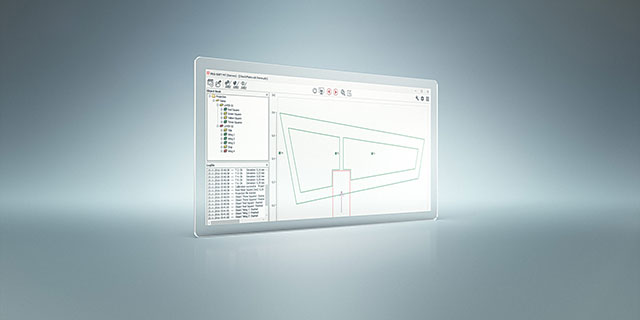

The use of laser projection systems by LAP and the know-how provided with them accelerate all positioning procedures during production and processing of composite parts. Step by step, your process is visualized directly on the surface of your workpiece. You prevent errors and increase the quality of your products.

Key figures

0

systems in use

0

countries already equipped

0

customer sites equipped

0

years of experience

Get a competitive edge by using laser technology

LAP laser projection systems let you reach a competitive edge by optimizing production processes. For positioning tasks, you can replace physical templates, measurement procedures or permanant consulting of manuals by showing outlines, positions and information on the surface of your workpiece. Independent of task, material and product, you will work faster, more flexible and cleaner as only laser light touches the surface of your tool or object.