Our worker guidance systems increase efficiency in control cabinet assembly by up to 30 percent. Time-consuming manual mounting of parts and wiring becomes simple and quick. This allows for economical production even at small lot sizes.

Acceleration of switch cabinet construction with ASSEMBLY PRO

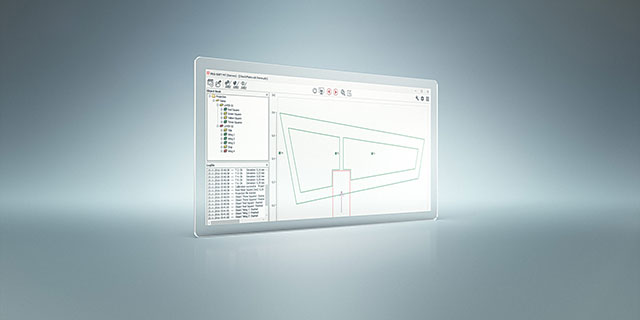

The assistance system ASSEMBLY PRO projects assembly instructions directly onto the mounting plate. Based on your CAD data, our laser pattern projectors show the exact positions of electrical components and the build sequence. If required, digital assembly instructions or work plans, 3D CAD data, videos, photos, or e-plan documentation can be digitally provided to the operator.

A laser-based assembly assistance system is especially helpful for the following work steps:

- Mechanical preparation of the control cabinet and switchboard panels, drilling template display

- Displaying length and position of cable ducts and terminal blocks

- Electrical component mounting position display

- Projection of wiring information

- Projection of equipment identification label and name plate application