How can CONCRETE PRO support you?

Our CONCRETE PRO solution supports the precise placement of elements on rotating pallets. One to two CAD-PRO laser projectors at each working station enable large-scale projections based on your CAD data. At the casing site, our laser pattern projectors exactly display all form parts onto the pallets. At the work stations for reinforcement and components, laser projectors visualize where the workers need to place armoring, electrical sockets, or wiring ducts. Similarly, cut-outs for windows and doors are precisely shown by means of laser contours.

For quality assurance, our laser projectors can control the presence, correct position, and orientation of all elements after pouring the concrete. This is especially important for collision control in double wall production: in order to ensure that, on the one hand, each wall fits properly to the other half and that, on the other hand, reinforcing bars or mounting parts do not collide when joining.

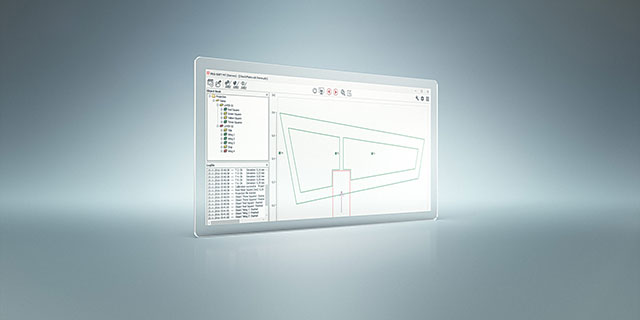

Our PRO-SOFT software also takes into account different heights of the components and visually compensates for differences. Another function of our system: as a circulating pallet arrives at the casing site, a reference projection allows you to adjust the image prior to projecting the actual set-up task. The reference projection can easily be adapted by remote control.