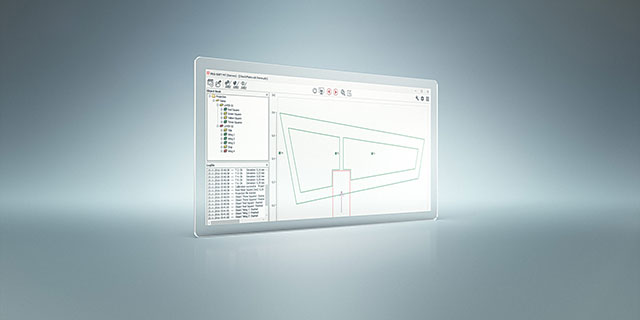

Laser projection systems enable you to produce faster, cleaner and more flexible than with other procedures. Accelerate your processes and improve the quality of your products. Use your CAD data to project outlines directly onto your workpiece instead of manufacturing conventional templates.

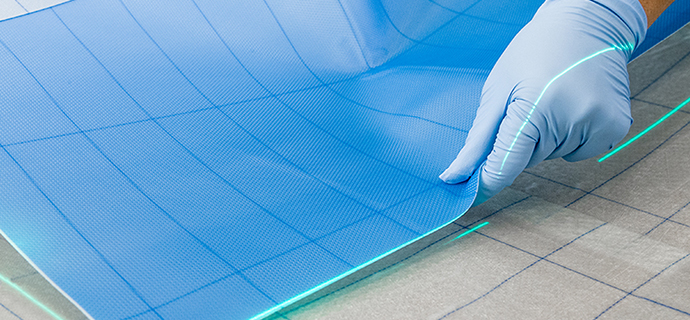

COMPOSITE PRO - the digital laser template for composite materials

COMPOSITE PRO is a laser system for projection of polylines and outlines on working surfaces and workpieces. Projected laser lines are a true to scale image of CAD data. Laser template projectors replace conventional templates and measuring aids used for placement. The complete process of planning, manufacturing, storing and managing physical templates and measurement equipment is a thing of the past. Changes in design just require a new version of the related projection file. Even small batches or prototypes can be handled easily.