How can our laser positioning systems support you?

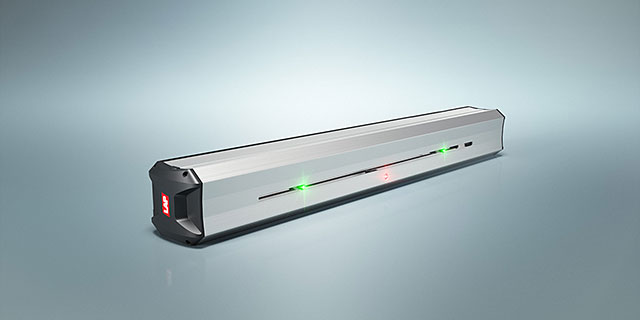

Are you preparing your tire production for future requirements? Our movable laser positioning systems help you meet the highest demands for durability, safety, and driving performance. Benefit from our 25 years of market experience with more than 2,500 integrated laser positioning systems at leading tire manufacturers around the globe. Use laser technology from LAP for manual rubber layup and quality control. Our laser systems ensure the highest possible positioning accuracy and thus provide constant, reliable production quality. You can produce faster and more precisely while reducing rejects.

Whether installing new systems or modernizing existing machines, we and our partners work with you to integrate the right solution into your tire building machine – regardless of the machine type, or tire size or type. This keeps you flexible and optimally prepares your production for future requirements.