Higher productivity in precast concrete parts production

CONCRETE PRO for precise positioning of elements on pallets and tables, flat beds or decks

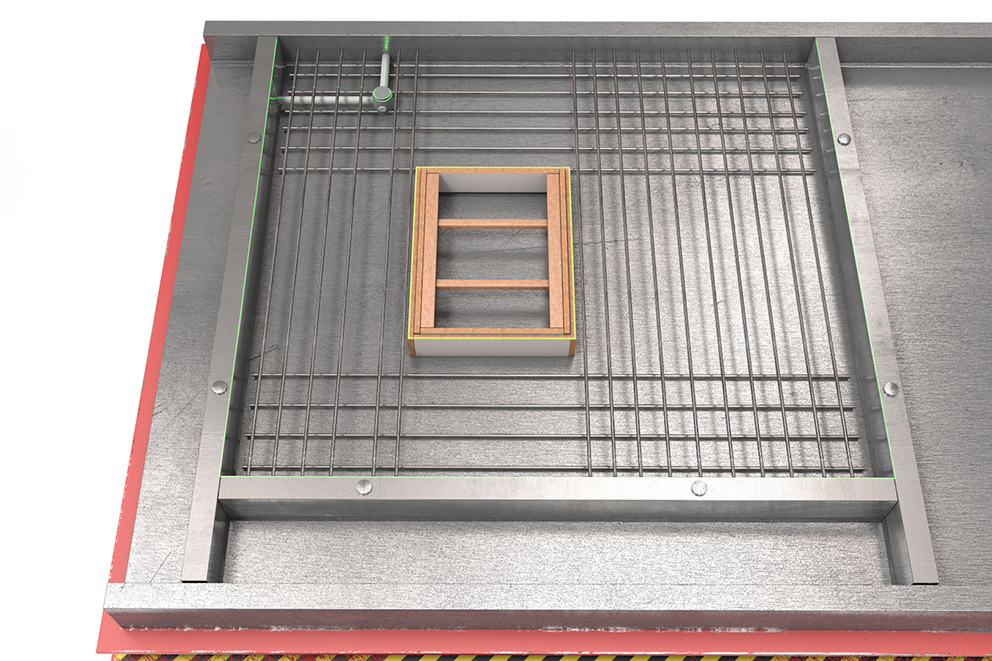

Precast concrete parts factories must produce large quantities of the same quality in an ever-shorter time. Manufacturing tolerances in the production of wall elements, ceilings or double walls must be precisely adhered to. Even in highly automated manufacturing, parts are still placed manually on pallets. In order to meet the demand for high component quality and cycle times, more and more plants worldwide are implementing laser projection systems. These systems eliminate the need for manual measuring by means of a tape measure and optimize efficiency throughout the entire production cycle.

As a laser technology specialist, LAP produces laser projection systems for the world market, which are used in diverse manufacturing industries. The CONCRETE PRO solution has been specially optimized for the requirements of the precast concrete industry. LAP laser projection systems are used at various workstations, ranging from placement of formwork, positioning of components and display of cut-outs to placing reinforcements. Finally, they also check the presence, correct positioning and orientation of all elements before filling with concrete. This is especially relevant for double wall production in order to ensure that, on the one hand, each wall fits properly to the other half and that, on the other hand, reinforcing bars or mounting parts do not collide when joining.

Read the full article how laser projection increases efficiency in precast concrete parts production.

The article has been published in: BFT International 11/2017