Increase efficiency with laser-based assembly assistance for control cabinet manufacture

Read the technical artical and learn how a ASSEMBLY PRO worker guidance system cuts time throughout the entire control cabinet production process

Producing and assembling control cabinets can be much more efficient with the help of digitalization. Laser-based assembly assistance systems can form part of an overall digitalization strategy. These systems provide an effective way to reduce process costs with quick and easy implementation. Especially small- and medium-sized businesses can benefit from a low-cost automation solution for “Switch cabinet manufacture 4.0” today.

In control cabinet construction, the process cost component can be as much as 80 percent. Labeling the components, mounting them on top-hat rails and connecting them by wire are time- and labor-intensive processes. According to the ISW study “Schaltschrankbau 4.0”, 49 percent of all working time is spent just on wiring the components. Of that, about 30 percent is preparation. Furthermore, components and switch cabinet configurations vary greatly. Over 60 percent of businesses surveyed stated a high proportion of customized constructions. But switch cabinet manufacture has remained largely analog. Paper-based methods continue to be widespread to this day. Implementing an automation solution, and doing so economically, is a complex challenge for many businesses.

Particularly SMEs benefit from time savings

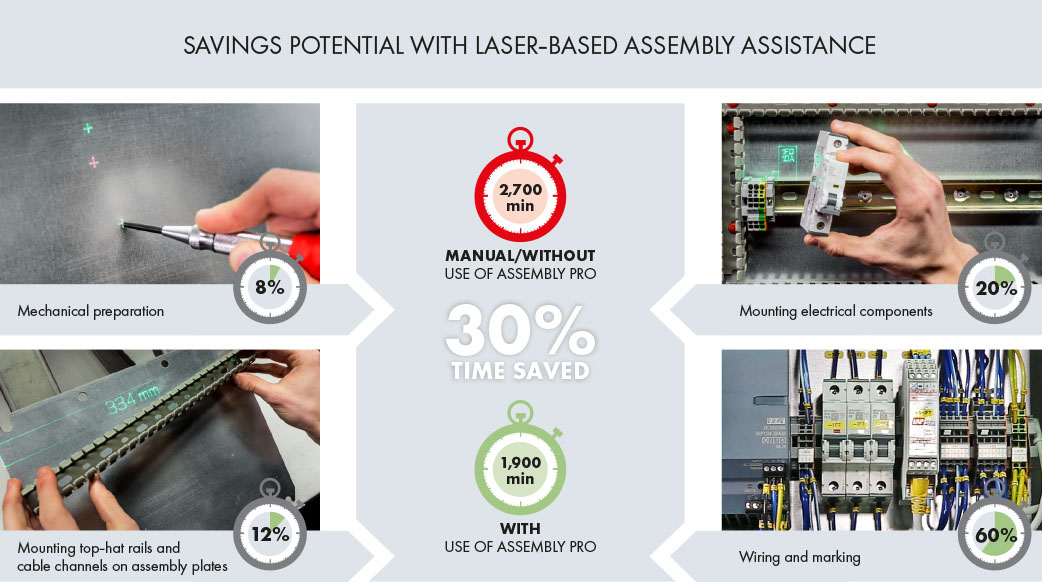

Unlike full automation, laser-based assembly assistance is a lowcost automation solution. It can make the mostly manual control cabinet production process more efficient without replacing human labor. Rather, operators receive better visual support to carry out time-intensive assembly processes in a safer, faster way. This has a significant impact, especially for businesses with 10 to 50 employees and a high proportion of manual assembly work. On average, an efficiency increase of up to 30 percent can be attained. This solution also supports shorter delivery times, even for small batch sizes, in the spirit of the Industry 4.0.

Faster assembly processes with digital data

This is where the ASSEMBLY PRO laser-based assembly assistance system really gets started. It can be used to produce and equip terminal boxes, compact cabinets, and free-standing enclosures. The system uses laser projection data based on digital CAD data. Laser projectors display these data directly onto the mounting plate, showing the exact position of the components and the build sequence. Additionally, digital assembly instructions and further information can be shown as text or graphics.

A laser-based assembly assistance system is especially helpful for the following work steps:

- Mechanical preparation of the control cabinet and switchboard panels, drilling template display

- Drill holes for terminal blocks and cable ducts are precisely displayed on the mounting plate. It is no longer necessary to mark the drilling template or work with stencils.

- Displaying length and position of cable ducts and terminal blocks

During assembly of cable ducts and rail mountings, the correct length and position of the rail mountings are projected directly onto the mounting plate, providing the operator with visual guidance. - Electrical component mounting position display

Displaying the mounting position directly on the terminal blocks saves the operator the effort of checking in the manufacturing documents. The component position is displayed precisely on the mounting plate, along with information about the component type and the equipment identification. - Projection of wiring information

Routing information display supports the most time-consuming task in control cabinet construction. - Equipment identification label and name plate application

According to the ISW study, up to nine percent of total production time is used for labeling. The laser-based assembly assistance system removes the need to look up individual positions using paper documentation.

Four steps to implement a laser-based assembly assistance system

A laser-based assembly assistance system can be installed and used at reasonable cost and with relatively little effort. For the system to be implemented, e-plans must be available as CAD files. Original CAD files can be processed in any common CAD program in the DXF exchange format. Good results can be achieved even with 2D CAD templates. LAP also provides a free plug-in for the low-cost CAD program Rhinoceros 3D, which supports the work flow and system control process.

Profitability

According to the ISW study “Schaltschrankbau 4.0”, wiring and mechanical placement offer great potential for optimization, since about 75 percent of the required work time is spent on these steps.

An additional 14 percent of work time is used for mechanical processing and inspection. The mounting and wiring steps can benefit most from digitalization here: for example, in the form of a visual display. In this area, a third of work time is lost to reading documents. According to ISW’s analysis, a digital document folder could reduce search time by up to 81 percent. Savings can be made throughout the entire control cabinet production process with consistent use of a laser-based assembly assistance system, cutting time by up to 30 percent. As a result, a typical ASSEMBLY PRO system can start turning a profit after just 25 switch cabinets.

Focus on the human being

Laser-based assembly assistance systems are a low-cost automation solution that increases efficiency and process security for manual production processes. They can be implemented as part of an overall digitalization strategy in Industry 4.0. This digital solution supports workers in carrying out their daily activities and reduces time spent on completion. It focuses on the human being, who — by bringing his or her experience, problem-solving skills and flexibility to bear — forms an essential component of versatile production processes of today and tomorrow.

This technical paper has been published in the 5/2018 edition of SCHALTSCHRANKBAU.

Authors: Dipl.-Ing. Patent Engineer Ralf Müller-Polyzou, doctoral candidate, Institute for Product and Process Innovation (PPI) Leuphana University of Lüneburg, and B. Eng. Steffen Gärtner, Product Manager, LAP GmbH Laser Applikationen.