Laser projection streamlines NP Nilsson's roof truss production

The Swedish company improves manufacturing efficiency through LAP’s CAD-PRO laser systems.

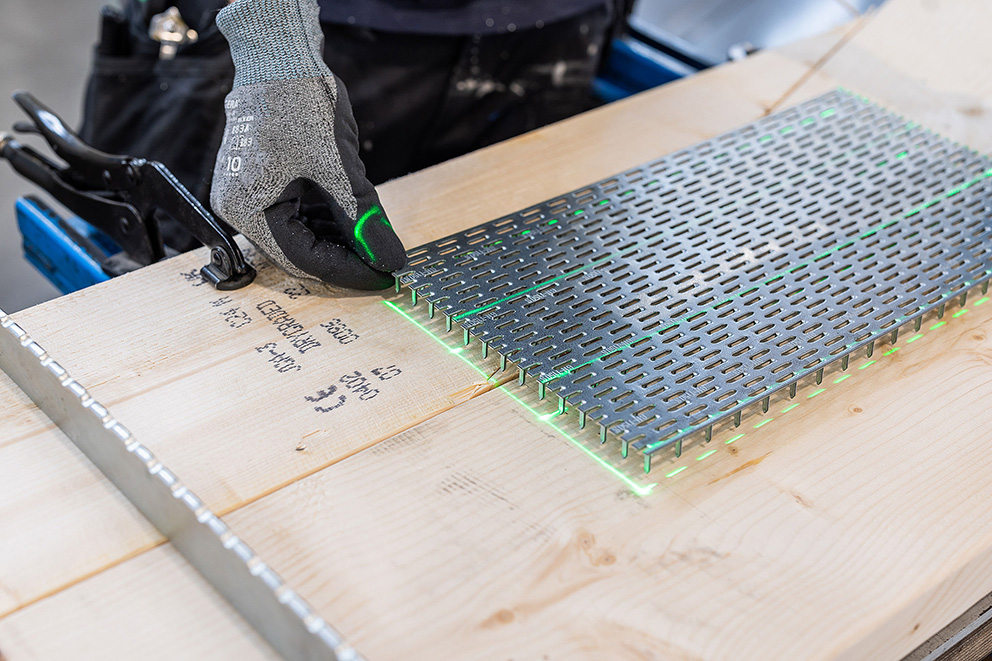

NP Nilsson, a family-owned Swedish company specializing in roof trusses, prefabricated walls, and custom-built packaging, sought a tailored solution to enhance efficiency in its roof truss manufacturing process. By integrating LAP's CAD-PRO laser systems with RANDEK's "Truss System NT" across four workstations along a 60-meter press area, NP Nilsson noticeably optimized its production workflow.

"Our decision to invest in this product is tied to our exclusive focus on custom projects," explains Mikael Roesberg, Production Manager at NP Nilsson. "Since setup time represents a substantial part of our production time, this solution met all the criteria we established from the beginning."

The workflow is straightforward and intuitive: once the design team finalizes the roof truss drawings, a single click exports a laser file. When assembly begins, the operator downloads the file, and the laser projects the press plate positions directly onto the work surface, enabling the operator to place the plates and timber precisely before pressing. Production staff can effortlessly manage all projection steps through the intuitive interface of LAP's PRO-SOFT software. Furthermore, remote controls at the stations support ergonomic working

This solution not only simplifies daily operations but also improves efficiency. As Roesberg summarizes: "With the laser, we can immediately detect if a plate is misplaced, receiving real-time feedback. This has resulted in a more efficient production process, reducing setup times."

See the application video here and find out more about laser projection for timber truss production.