PLCs control assistance systems in the Digital Factory

The integration of industrial laser assistance systems for worker guidance into the control layer opens up interesting possibilities of digital transformation for manufacturing companies, especially for small and medium-sized enterprises (SMEs). These possibilities are illustrated using the example of the „Digital Factory“ of the Leuphana University Lüneburg.

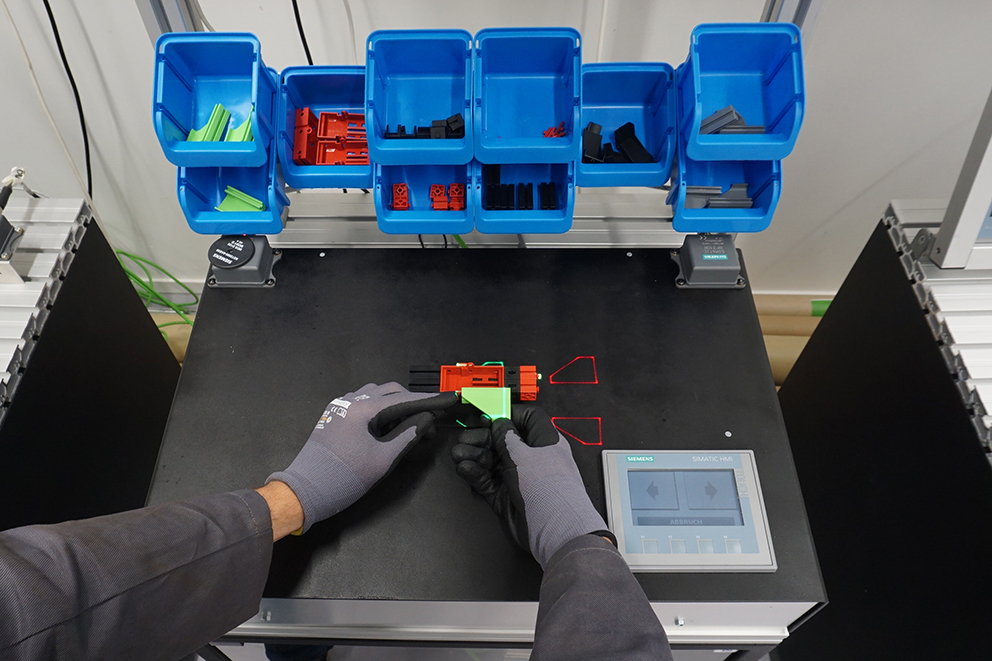

In the practice project a manual assembly station using an industrial laser assistance system was developed and integrated into the SIMATIC control level of the digital factory. At the assembly station, the assembly of an automobile is simulated on the basis of a car model. The worker interacts with the assistance system, which guides him or her through the order-related assembly process.

The laser assistant system is controlled by the software controller via a proprietary TCP/IP protocol. It supports commands that allow, amongst others, the calibration, the loading of projection files as well as forward and backward switching of laser projections. The operator interacts with the system by means of HMI commands and canuse the touch panel to call up the next assembly step, for example.

Orders are also generated at an upstream station via Human Machine Interface (HMI). Each order is stored on an industrial RFID chip. The assembly status of the object is updated on the RFID chip and can be evaluated at any time of the production process.

The full article is available in German language as PDF download. It describes the results of the practice project and the potentials of horizontal and vertical integration of industrial laser assistance systems for worker guidance into the control level. Published in: Industrie 4.0 Management, 35. Jahrgang, 2019, Ausgabe 4, Seite 13-16, Authors: Ralf Müller-Polyzou, Nicolas Meier, Felix Berwanger und Anthimos Georgiadis, Leuphana Universität Lüneburg;