With laser technology and know-how by LAP you will gain safety and quality for your processes and products. Start using state of the art projection tools to prevent errors and to optimize your throughput.

Key figures

+0

Systems in use

0

countries

+0

customer sites

0

years of experience

Competitive advantages with laser projection systems

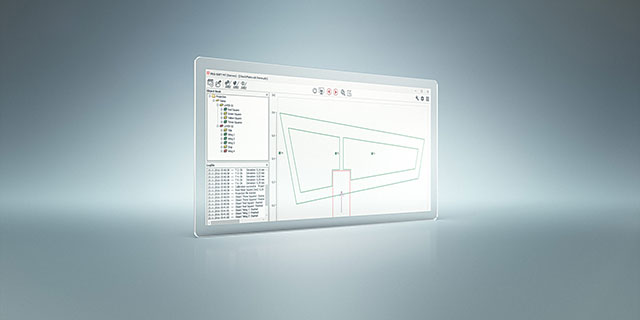

Laser projection systems by LAP offer the possibility to reach a competitive edge by optimizing production processes. Physical templates, measurement tasks or permanent consulting of manuals are things of the past. Simply show outlines, positions and information on the surface of your workpiece. Independent of task, material and product, you will work faster, more flexible and cleaner with laser template projectors than with conventional templates or measuring aids.