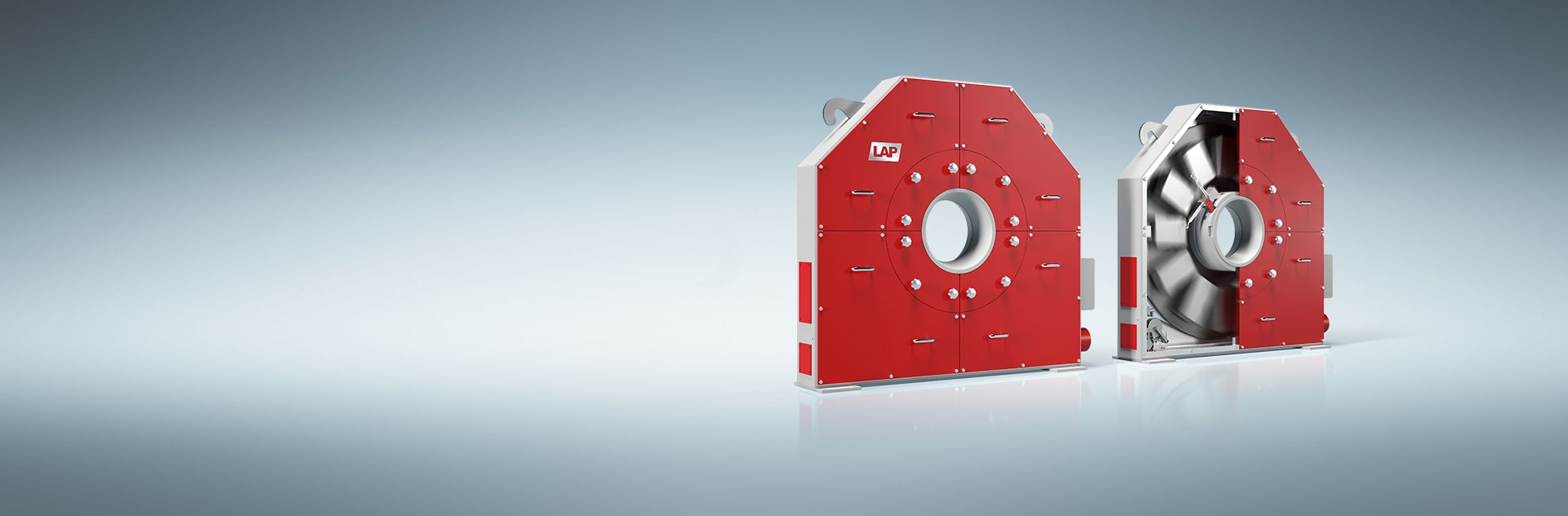

Our worldwide approved solution for real-time profile measurement

Laser measuring systems are of central importance for rolling mills to check the contours of steel profile for defects during the production process. A slight deformation on the surface of the profiles reduces the quality of the product, and in the worst case, a broken roll can even destroy the entire batch. With our systems CONTOUR CHECK ROUND & EDGE you identify and evaluate deviations at an early stage. Increase the process efficiency of your production - regardless of temperature and profile shape.

CONTOUR CHECK ROUND is the established solution for measuring round profiles and rebar. Three- and six-axis versions can also accurately record profiles from three point rolling processes.

CONTOUR CHECK EDGE uses sensors on a base plate that rotates in an oscillating manner. In this way, square, flat or hexagonal profiles are measured. Both systems are based technically on the shadowing principle.

SMART CORE ADVANCED Software

The software shows the profile cross-section, numerical values, and production process, and indicates whether the quality criteria are met. The measurement system can also be connected to data mining systems such as Level 2 and iba.

Technical data

| CC ROUND 45 | CC ROUND/EDGE 90 | CC ROUND/EDGE 120/150 | CC ROUND/EDGE 180/230 | CC ROUND/EDGE 500 | |

| Measuring range | 45 mm | 90 mm | 120 mm/150 mm | 180 mm/230 mm | 500 mm |

| Accuracy (trueness) | ±0,015 mm | ±0,020 mm | ±0,025 mm/±0,030 mm | ±0,035 mm/±0,045 mm | ±0,090 mm |

| Repeatability (precision) | 0,004 mm | 0,0045 mm | 0,005 mm/0,008 mm | 0,010 mm/0,012 mm | 0,025 mm |

| Number of axes | 2, 3, 4, 6 | 2, 3, 4, 6 | 2, 3, 4, 6 | 2, 3, 4, 6 | 2, 3, 4 |

| Frame width | 860 mm | 1240 mm | 1720 mm | 2250 mm | 2550 mm |

| Frame height | 940 mm | 1170 mm | 1685 mm | 2215 mm | 2515 mm |

| Frame depth | 81 mm | 253 mm | 253 mm | 253 mm | 253 mm |

| Passline height | 450 mm | 570 mm | 835 mm | 1100 mm | 1250 mm |

| Frame weight | 125 kg | 580 kg | 930 kg | 1500 kg | 1900 kg |

| Positioning system | Yes | Yes | Yes | Yes | Yes |

| Blower | Yes | Yes | Yes | Yes | Yes |

| Air cooling unit | Optional | Optional | Optional | Optional | Optional |

| Pyrometer (optional) | Yes | Yes | Yes | Yes | Yes |

CONTOUR CHECK ROUND for round profiles and ribbed steel

Learn more about the CONTOUR CHECK ROUND features