New XtrAlign HU line laser for demanding industrial use

Proven optics in a robust housing – the new generation of laser from LAP brings together the best of two worlds: long, even laser projection and the robustness of the XtrAlign series. LAP will present the HU for the first time at Ligna (hall 15, stand B06).

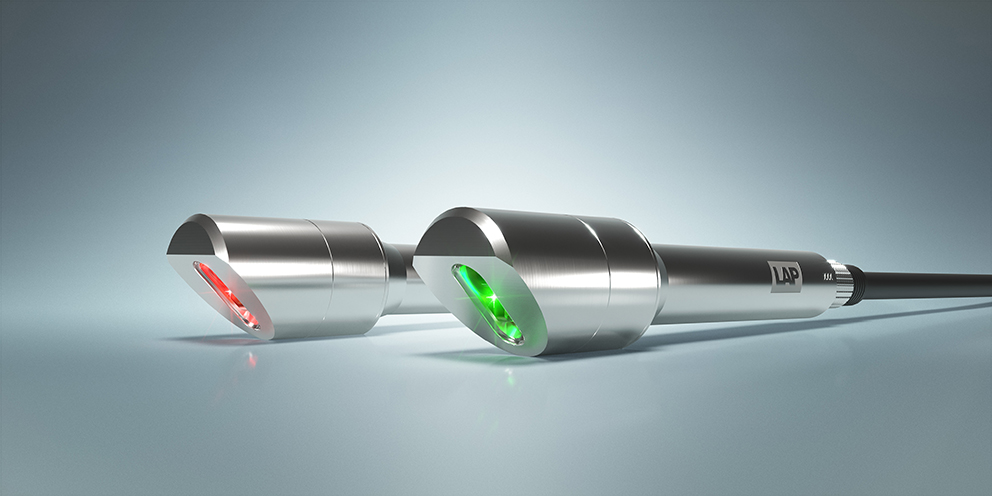

A new addition to the LAP XtrAlign laser family: the XtrAlign HU laser combines the unique optics of the proven ULTRALINE laser with all the advantages of the XtrAlign family. Protection class IP67-rated stainless steel housing, a green laser diode for greater visibility, and straightforward integration result in even more process reliability for the most demanding production environments.

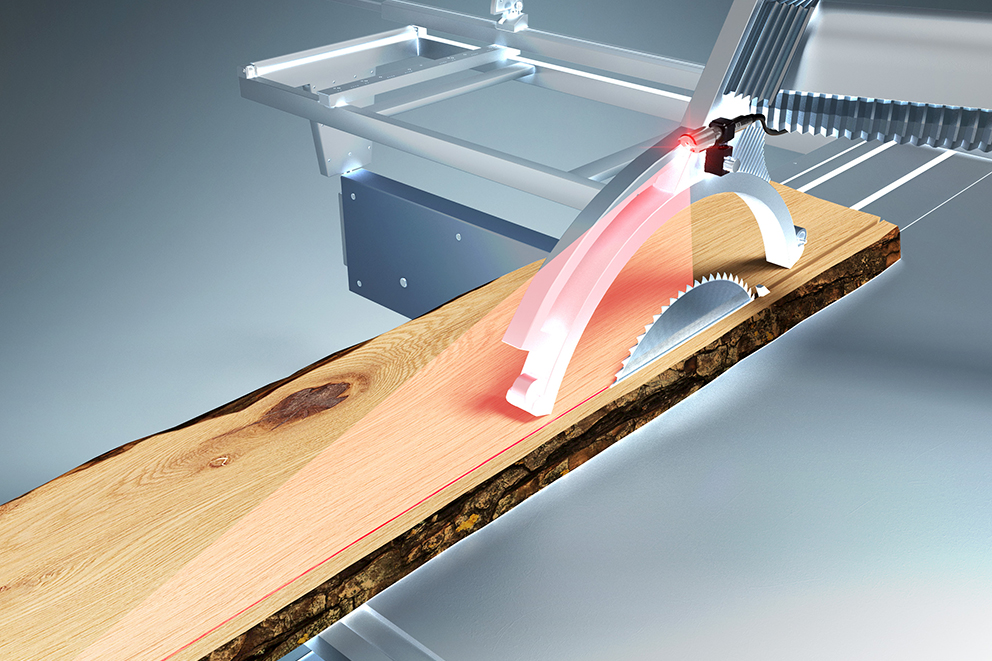

With the XtrAlign HU, LAP is presenting the successor generation to the ULTRALINE laser, which has been successfully used in industry and manual craft for more than 20 years. Just like the ULTRALINE, the HU offers long, even line projection at low installation heights. This means that this line laser is specifically destined for integration into processing machines, as required in the wood, steel and other industries. LAP has now integrated the unique optics of the ULTRALINE into the housing of the XtrAlign family, with the result that the HU can be used in even the most demanding industrial conditions.

Unique ULTRALINE optics now in an IP67-rated housing

The robust stainless steel housing of the HU is rated at protection class IP67 – greater than the ULTRALINE at IP54 – meaning that it is waterproof and dustproof, as well as resistant to temperatures up to +40°C. With class IK10, the HU offers the highest level of protection against external mechanical impact. Thanks to the new design, the HU can be aligned effortlessly and even more precisely during installation on the machine.

Better visibility thanks to a green laser diode

Another novelty is that the HU is available with either a red or green laser diode. Customers who already use the ULTRALINE benefit from the long service life of the green laser diode, which offers more than 30,000 operating hours. In addition, the green diode provides better visibility on dark surfaces and in brightly lit workspaces, making the process significantly faster, and resulting in increased efficiency and therefore cost savings for the customer. As with the XtrAlign HY, the green laser source of the XtrAlign HU is also dimmable. This means that the laser projection can be optimally adapted to each specific use case, ensuring greater precision and improved process reliability.

Straightforward machine integration

As with all the positioning lasers in the XtrAlign family, the HU can be operated at 12 to 30VDC. This ensures very easy integration into existing systems. When using standard brackets, replacing the ULTRALINE with the HU is a straightforward process, and requires no adaptations to the processing machine.

Predestined for demanding production environments

These features make the HU ideally prepared to efficiently go to work, even in demanding production environments. Sawmills benefit from the advantages of the HU for the precise indication of cutting edges on the wood processing machine. In the steel industry, the HU can also be used to display the cutting edge of a shear press on heavy plate roller tables. The operator can then adjust the shear in such a way that the greatest possible material output is achieved.

The use of lasers from the XtrAlign family enables process quality and reliability to be increased, and costs to be consistently reduced through the avoidance of scrap. In addition, the lasers can be easily integrated into almost any application with minimum effort. Thanks to the long service the HU can be used in continuous operation, requiring no further maintenance or care. A 24-month guarantee applies for all lasers in the XtrAlign family – including the HU of course.