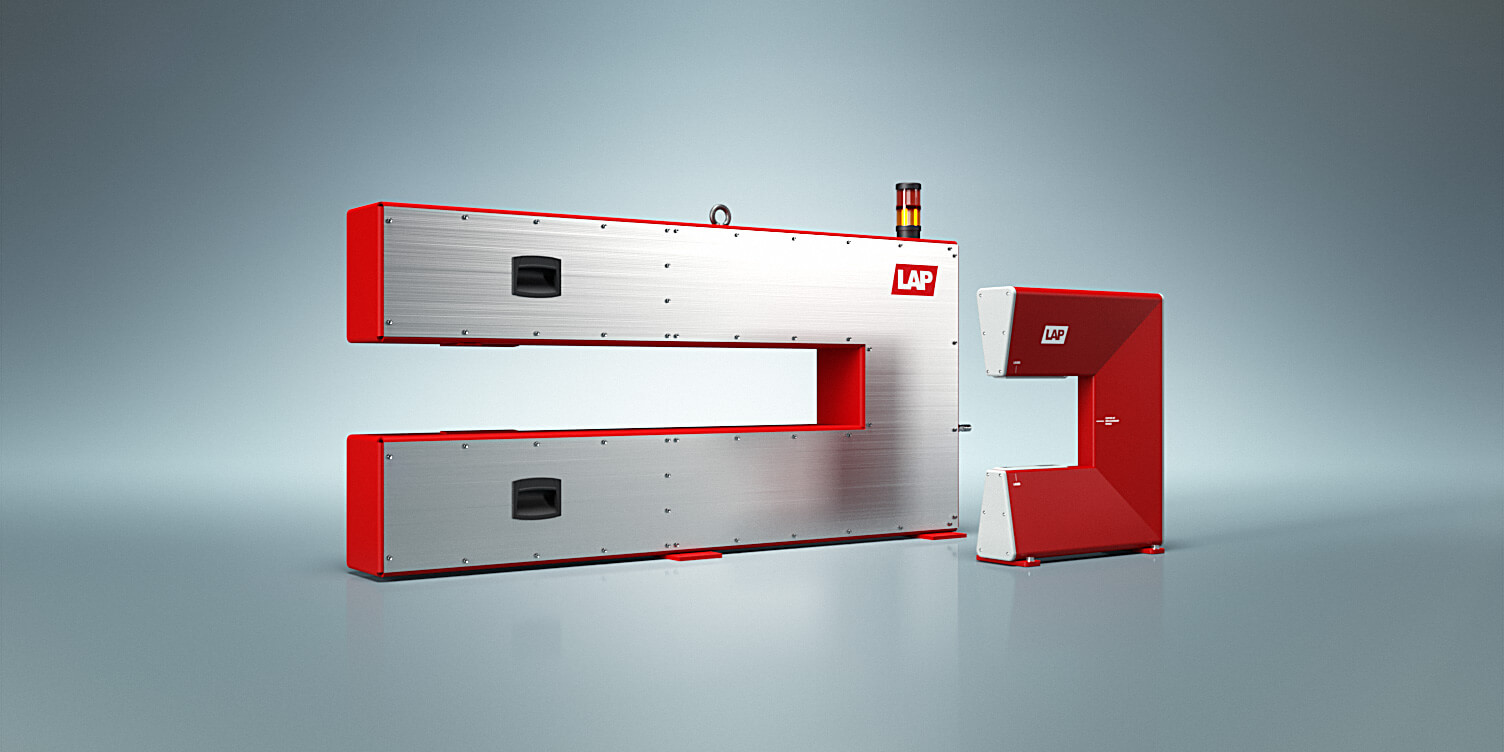

Thickness measurement in real time – witout the need for radiation protection

Exact thickness measurement is important at many stages in the manufacture and processing of strip; in rolling, pickling and annealing, on wrapping and inspection lines, in organic and anorganic coating, and on slitting and cross-cutting lines. In addition to the absolute thickness, information is needed on the shape of the cross section – wedge and crowning.

In rolling, real-time thickness measurement on both sides of the stand is critical for fast adjustment of the stand. Users today generally expect a measurement precision of a few micrometers. Radiometric systems have been in use for decades, and meet accuracy needs. But they have two big disadvantages – the workload of entering material parameters, and the cost of radiation protection.

Thickness measurement by laser is superior to established radiometric systems in several ways. Regardless of the material properties of the strip, laser systems give equivalent or higher precision and require no radiation protection measures. Their local resolution is also substantially higher, since the 0.08 mm measuring spot diameter is much smaller than with radiometric systems. Among other things, this means that measurements are possible very close to the strip edge.