Your guarantee of quality for the thickness measurement of sheet metal and strip steel

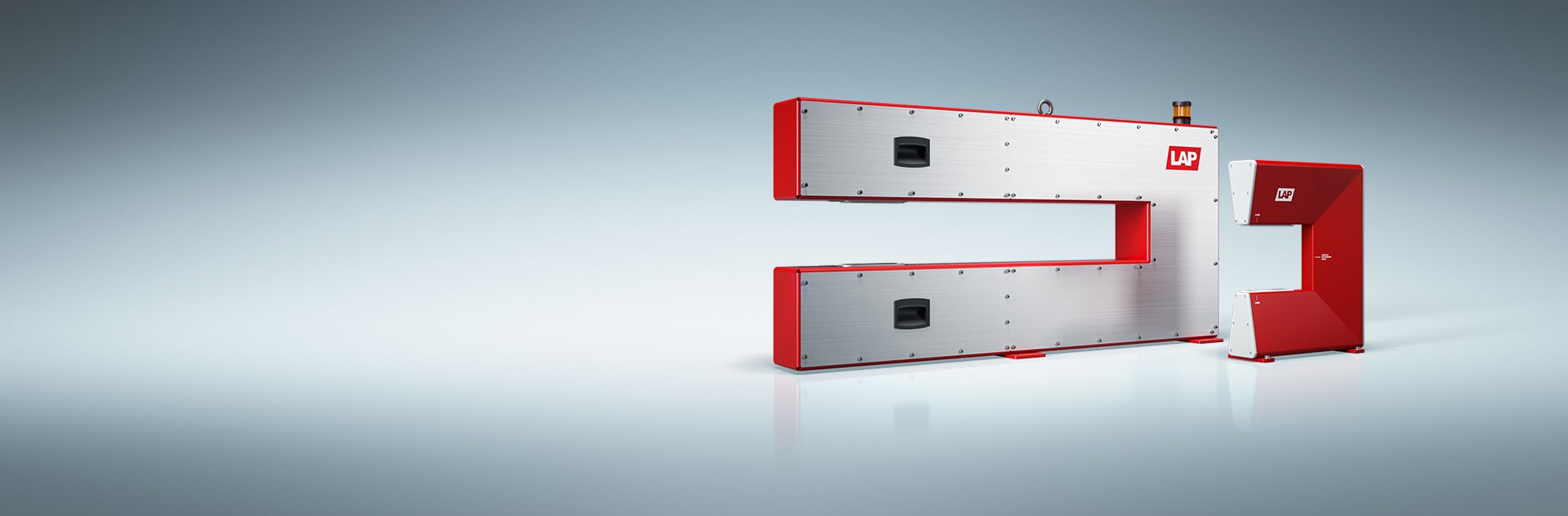

For the manufacturing of a perfect cold strip, many factors are crucial. Our measuring frames specifically check the thickness-related quality parameters of the strip steel or steel sheet. Free of radioactive radiation, laser sensors are used in the cold strip areas that usually do not require protective measures for laser class 2.

The installation of our measurement systems is quick and uncomplicated for our customers. The CALIX is integrated into the line with its C-shaped frame across the material flow. Our solutions with and without traversing determine all important parameters for quality assurance, including strip thickness, edge thickness, wedge or cambering, and measure the complete thickness profile. Thus, you have full process control in the current production.

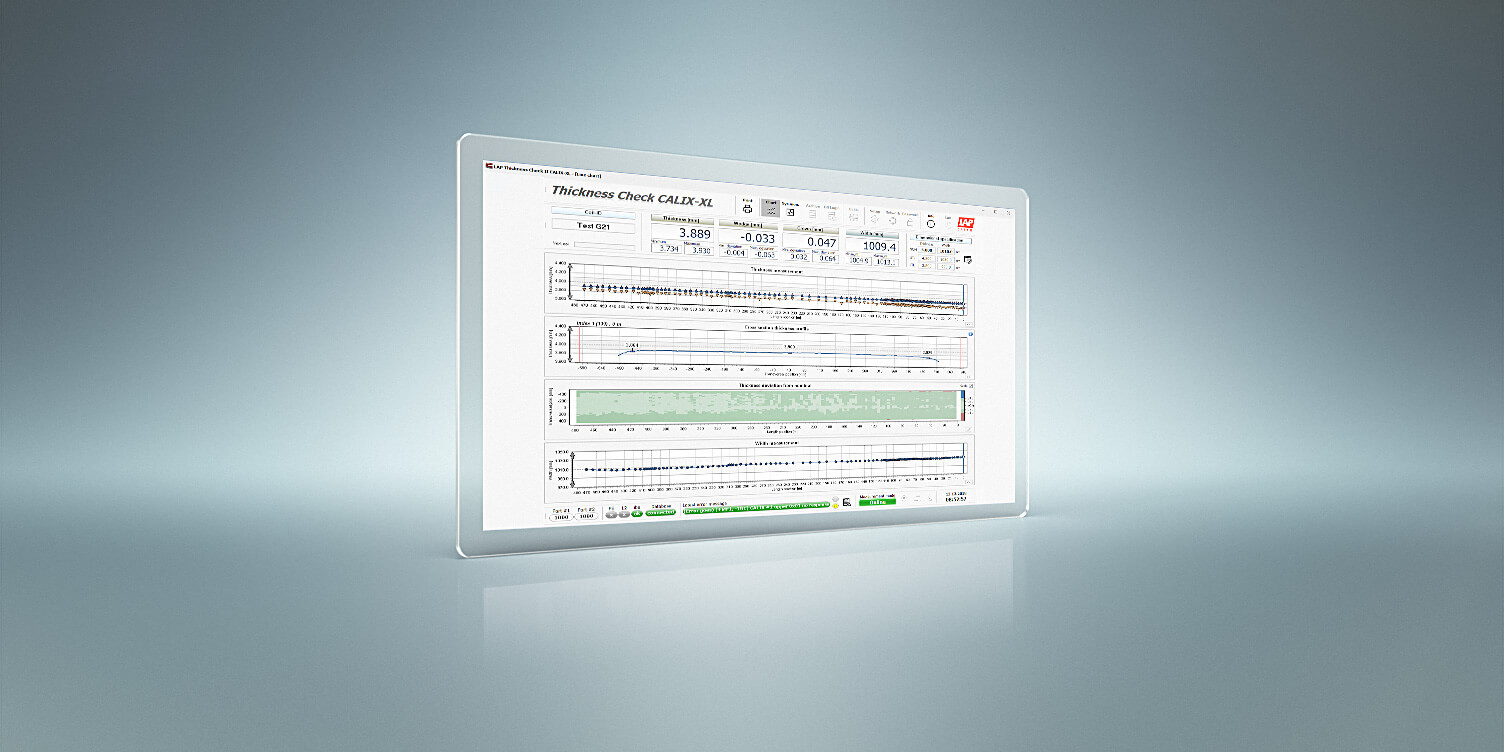

THICKNESS CHECK software

The laser sensor transmits up to 4000 measured values per second to the software. You will receive a detailed evaluation with all measured minimum, maximum and average values. In addition, the standard deviation as well as the Cp and Cpk values are calculated.

Technical data

| CALIX S | CALIX XL | |

| Measuring range [mm] | 30 | 30 |

| Accuracy (trueness) [µm] | ±2.5 | ±2.0 |

| Repeatability (precision) [µm] | 0.35 | 0.35 |

| Resolution [µm] | 0.5 | 0.5 |

| Throat depth / height [mm] | 297 / 201 | 1300 / 200 |

| Measuring depth [mm] | 256 | 1090 |

| Passline height [mm] | 316 | 390 |

| Frame dimensions (WxHxD) [mm] | 140 x 623 x 514 | 207 x 800 x 1645 |

| Frame weight [kg] | 20 | 220 |

| Laser type | red diode | red diode |

| Available laser classes | 2 / 3B | 2 / 3B |

| Max. measuring frequency [kHz] | 4 | 4 |

| Max. material temperature [°C] | 200 | 200 |

| Calibration unit (offline and inline) | yes | yes |

| Comprehensive software | yes | yes |

| Data interfaces | RS485, Ethernet (TCP/IP, UDP, OPC UA, iba) | RS485, Ethernet (TCP/IP, UDP, OPC UA, iba) |

| Positioning system | yes | yes |

| Air purge system incl. protection housing and blower | yes | yes |

| Cooling unit | yes | yes |

| Control panel | yes | yes |

| Windows PC-Set | yes | yes |