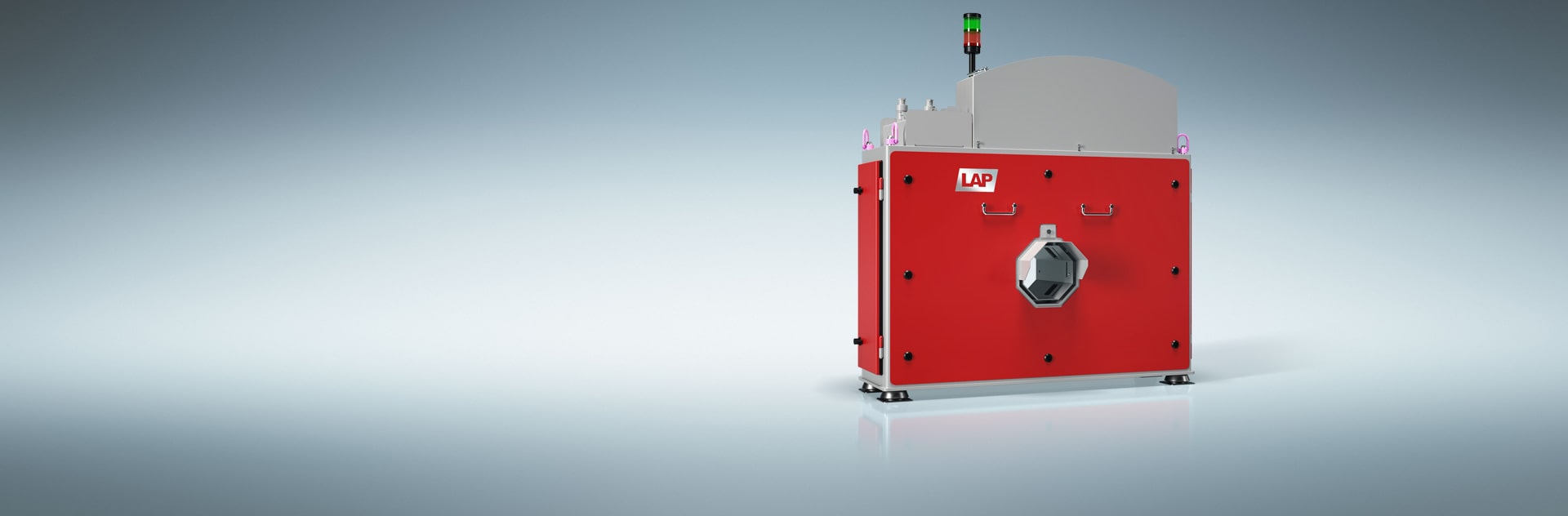

The pioneering measuring system for optical contour measurement and surface defect detection on long products of your steel profile

CONTOUR CHECK SHAPE has proven itself in hot rolling of long products and is an essential part of the rolling process in many factories. It checks hot and cold steel profiles with the help of three-dimensional surface reconstruction. It records dimensional errors due to rolling defects and surface defects such as rolling seams from calibre overfill, grooves, fire crack marks, rolling marks, and more.

The innovation lies in the optimized laser light section sensors which LAP constructs with its own laser technique and high-end industry cameras. The cross section is observed continuously by four cameras. The object to be measured is scanned lengthwise at a rate of 2000 Hz. The camera with high-speed image recording captures the laser line while the often still glowing steel enters the measuring field.

Regardless of the profile form (round, square, ...), the CONTOUR CHECK SHAPE supports your production process and verifiably reduces scrap. One additional feature is the precise measurement of rebar whereby measuring values like the contour of the core, the rib height and the weight per meter are accurately calculated.

Software SMART CORE PRO

The software offers the unique functionality of virtually rotating a rotating and vibrating round profile into alignment of the rolling mill to directly measure the real rolling defect. You can also configure the user interface individually. Learn more!

Technical data

| CC SHAPE 50 | CC SHAPE 100 | CC SHAPE 150 | CC SHAPE 250 | CC SHAPE 500 | |

| Measuring range | 50 mm | 100 mm | 150 mm | 250 mm | 500 mm |

| Accuracy (trueness) | ± 0,015 mm | ±0,025 mm | ±0,040 mm | ±0,065 mm | ±0,100 mm |

| Repeatability (precision) | 0,003 mm | 0,006 mm | 0,009 mm | 0,015 mm | 0,030 mm |

| Number of cameras | 4 | 4 | 4 | 4 | 4 |

| Frame width | 1270 mm | 1270 mm | 1470 mm | 1770 mm | 2400 mm |

| Frame height | 1280 mm | 1480 mm | 1680 mm | 2170 mm | 2590 mm |

| Frame depth | 370 mm | 470 mm | 550 mm | 640 mm | 745 mm |

| Passline height | 450 mm | 540 mm | 640 mm | 780 mm | 890 mm |

| Frame weight | 355 kg | 435 kg | 585 kg | 895 kg | 1370 kg |

| Positioning system | Yes | Yes | Yes | Yes | Yes |

| Blower | Yes | Yes | Yes | Yes | Yes |

| Air and water cooling unit | Yes | Yes | Yes | Yes | Yes |

| Pyrometer | Optional | Optional | Optional | Optional | Optional |